Understanding the Role of Steel Fabricators Near Me

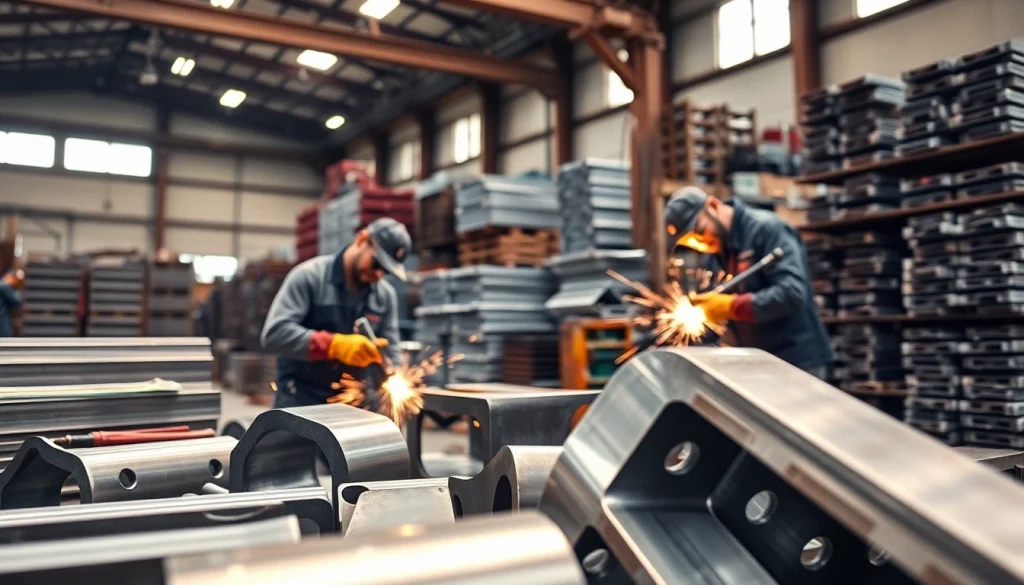

Steel fabricators are integral to the construction and manufacturing sectors, providing essential services that shape the backbone of various projects. Whether you are working on a large industrial job or a small-scale fabrication for a residential project, finding quality steel fabricators near me can significantly affect the outcome of your work. This article delves deeper into the functions and importance of steel fabricators, focusing on what they do, common applications of their services, and the advantages of hiring local fabricators.

What Steel Fabricators Do

Steel fabricators are craftsmen who work with steel and other metals to produce a variety of structures, parts, and components. This process often involves several steps, including:

- Designing: Understanding the specifications and requirements of the project, which often involves detailed planning and computer-aided design (CAD) systems.

- Cutting: Using various tools and methods to cut steel into specified dimensions.

- Welding: Joining pieces of steel together by melting the edges and fusing them.

- Finishing: Applying protective coatings and preparing the finished product for installation.

Steel fabricators must have a thorough understanding of metallurgy and mechanical engineering principles to produce safe, durable, and high-quality products. Their work may range from producing simple components to complex assemblies, all tailored to meet the unique demands of different industries.

Common Applications of Steel Fabrication

The applications of steel fabrication are nearly limitless, given the versatility of steel as a material. Common applications include:

- Construction: Structural elements such as beams, columns, and reinforcements that form the skeleton of buildings and bridges.

- Manufacturing: Components for machinery and equipment used across various sectors, including automotive, aerospace, and heavy equipment.

- Architectural: Customized metalwork for facades, staircases, and decorative elements that enhance the aesthetic appeal of buildings.

- Agriculture: Fabricated items for farming such as silos and supports for equipment.

The ability to tailor projects to specific needs makes steel fabrication a critical process in multiple industries.

Benefits of Hiring Local Fabricators

Choosing steel fabricators near me can provide numerous advantages, including:

- Proximity: Local fabricators can easily access job sites, which can reduce transportation costs and timelines.

- Personalized Service: Smaller, local businesses often focus more on customer service and establishing long-term relationships.

- Community Impact: Supporting local businesses contributes to the economy and job creation in your area.

- Quick Response Times: In emergencies or when adjustments are needed, local fabricators can typically respond faster than distant suppliers.

Key Characteristics of Quality Steel Fabricators Near Me

Experience and Expertise in the Industry

One of the first aspects to consider when looking for steel fabricators is their experience and expertise. A reputable fabricator should have a proven track record in their field, with the credentials to showcase their capabilities. This includes certifications in welding and fabrication, as well as a portfolio of completed projects that mirror your specific needs.

Experience often translates into knowledge about best practices, which can be invaluable. Experienced fabricators are likely to foresee potential challenges and provide solutions proactively, minimizing the risk of delays or failure.

Innovative Techniques and Technologies Used

The best steel fabricators are those who continuously invest in modern techniques and technologies that enhance their service quality. This includes:

- Automation: Utilizing automated machines and robotic welding to increase speed and precision.

- 3D Modeling: Employing advanced design software for accurate projections of the product before fabrication.

- Quality Control Technology: Implementing rigorous testing and inspection technology to ensure the integrity and quality of fabricated products.

Staying at the forefront of technology not only improves efficiency but also ensures higher quality results for clients.

Customer Reviews and Testimonials

Assessing customer feedback is a practical approach to gauging the reliability and quality of steel fabricators. Reviews can provide insights into their operational strengths and weaknesses. Look for patterns in feedback regarding:

- Quality of work

- Timeliness of project completion

- Customer service experiences

Testimonials from previous clients can shed light on how a fabricator handles challenges, communication, and overall project management.

How to Evaluate Steel Fabricators Near Me

Questions to Ask Before Hiring

Before selecting a fabricator, it is crucial to gather information that will help you make an informed decision. Key questions to consider include:

- What materials do you specialize in? Ensuring they can work with the specific types of steel you need.

- What is your turnaround time for projects? Essential for planning your project timelines.

- Can you provide references from previous clients? Gathering insights from past clients can provide a gauge of their performance.

- What warranties or guarantees do you offer on your work? Assurance for quality and post-installation support.

Comparing Quotes and Services Offered

When evaluating potential fabricators, obtaining detailed quotes from multiple companies is advisable. Look beyond the price—ensure that the quotes include a breakdown of services provided, materials used, and labor costs. Comparing quotes allows you to assess value for money effectively. Keep an eye out for:

- Inclusions and exclusions in the quote

- Hidden costs that may arise later in the project

- Differences in lead times which can affect project scheduling

Understanding Turnaround Times and Availability

Turnaround time is a pivotal factor when selecting a fabricator. Delays can derail project schedules and inflate costs. It is beneficial to ask about their current workload, available resources, and any potential factors that may slow down production. Manufacturers with flexible resources and efficient processes can better meet strict timelines.

Best Practices for Collaborating with Steel Fabricators Near Me

Preparing Accurate Design Specifications

Design collaboration is pivotal for the success of any fabrication project. Accurate and detailed specifications help fabricators understand your vision. Engage with designers or engineers who can provide comprehensive and precise drawings that include dimensions, material types, and finishes. This clarity minimizes miscommunication and ensures all parties are aligned.

Effective Communication Throughout the Project

Effective communication is essential for a smooth fabrication process. Establish a clear communication protocol at the outset and ensure that contact points are outlined. Regular updates on progress and any issues that arise can prevent misunderstandings and ensure that problems are resolved swiftly.

Ensuring Safety and Compliance with Industry Standards

Collaboration with steel fabricators should also prioritize safety and compliance with relevant regulations. Familiarize yourself with industry standards for welding and fabrication specific to your project type. Ensure that your chosen fabrication partner follows these guidelines to guarantee not just operational safety but also the durability and quality of the finished products.

Future Trends in Steel Fabrication Services

Emerging Technologies Impacting Steel Fabricators

The field of steel fabrication is evolving with advancements in technology. Emerging technologies such as Additive Manufacturing (3D printing) and Artificial Intelligence (AI)-driven efficiencies are beginning to reshape how fabricators operate. Fabricators who adapt to these changes will be able to offer more innovative solutions, higher efficiency, and cost savings to their clients.

Expanding Services: Sustainability Practices

As environmental concerns rise, many steel fabricators are adopting sustainable practices. This includes using recycled steel, minimizing waste through lean manufacturing processes, and implementing energy-efficient technologies. Partners that prioritize sustainability may also provide additional benefits, such as enhanced corporate responsibility profiles and appealing to environmentally-conscious consumers.

Adapting to Market Demands in Metal Fabrication

The market for metal fabrication is constantly changing due to developments in technology and shifting consumer expectations. Fabricators must keep a finger on the pulse of these trends to remain competitive. This might involve diversifying service offerings, expanding into new markets, or leveraging new materials to meet the rising demand for specialized products.